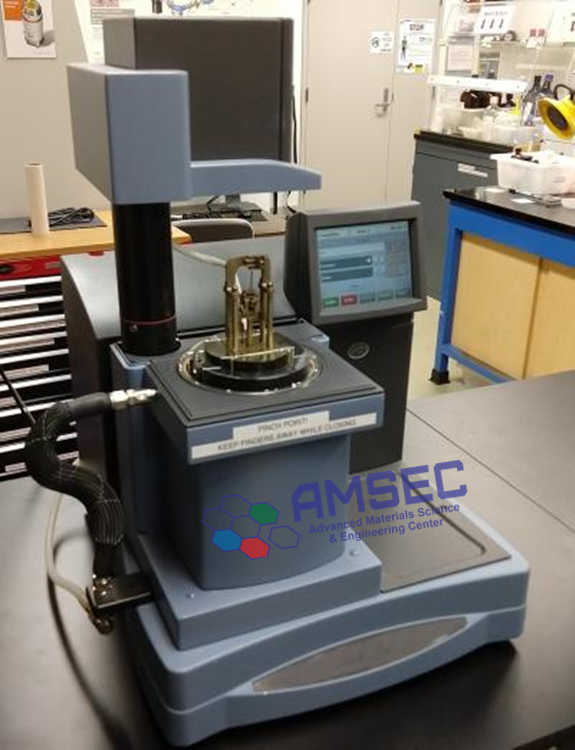

TA Instruments Q800

Dynamic Mechanical Analysis measures the mechanical properties of materials as a function of time, temperature, and frequency. In addition to basic material properties, DMA also quantifies finished part characteristics, reflecting the important contribution that processing has on end-use performance. DMA is commonly used to measure glass transition temperatures and secondary transitions, orientation caused by processing, cold crystallization, cure optimization, filler effects in composites, and much more. DMA provides an accurate measure of material stiffness (modulus) but also other important mechanical properties such as damping, creep, and stress relaxation. Currently, we have the tension, cantilever, 3-point bend, and compression clamps. If you would like more information please see the manufacturer's website.

Publication Acknowledgement

Please use the following statement in the acknowledgement section of any document generated which uses data collected from the Rheometer.

The authors acknowledge the use of the facilities, plus the scientific and technical assistance of the instrument staff at the Advanced Materials Science and Engineering Center, Western Washington University, USA. The authors also acknowledge the support of the Joint Center for Aerospace Technology Innovation for funding the TA Instruments Q800 Dynamic Mechanical Analyzer (DMA) used in this work.